Chapter 1: What is Spray Polyurethane Foam Roofing?

Spray Polyurethane Foam Roofing is a product that’s sprayed as a liquid so it can broaden into a foam, creating a solid layer across an existing roof.

The typical application of spray foam is to repair and reinvigorate an existing roof by getting rid of the saturated locations, replacing it with like products, and after that spraying foam over top of the entire Roof.

While SPF roofing is not the most recognized kind of roofing material, the technology has been around because the early 1960s for commercial, business, and residential centers. An SPF roofing system can be utilized in any environment, and when properly installed and preserved, can last over 50 years.

Spray Polyurethane Foam (SPF) for roofing applications is made on the Jobsite by blending two highly reactive chemicals.

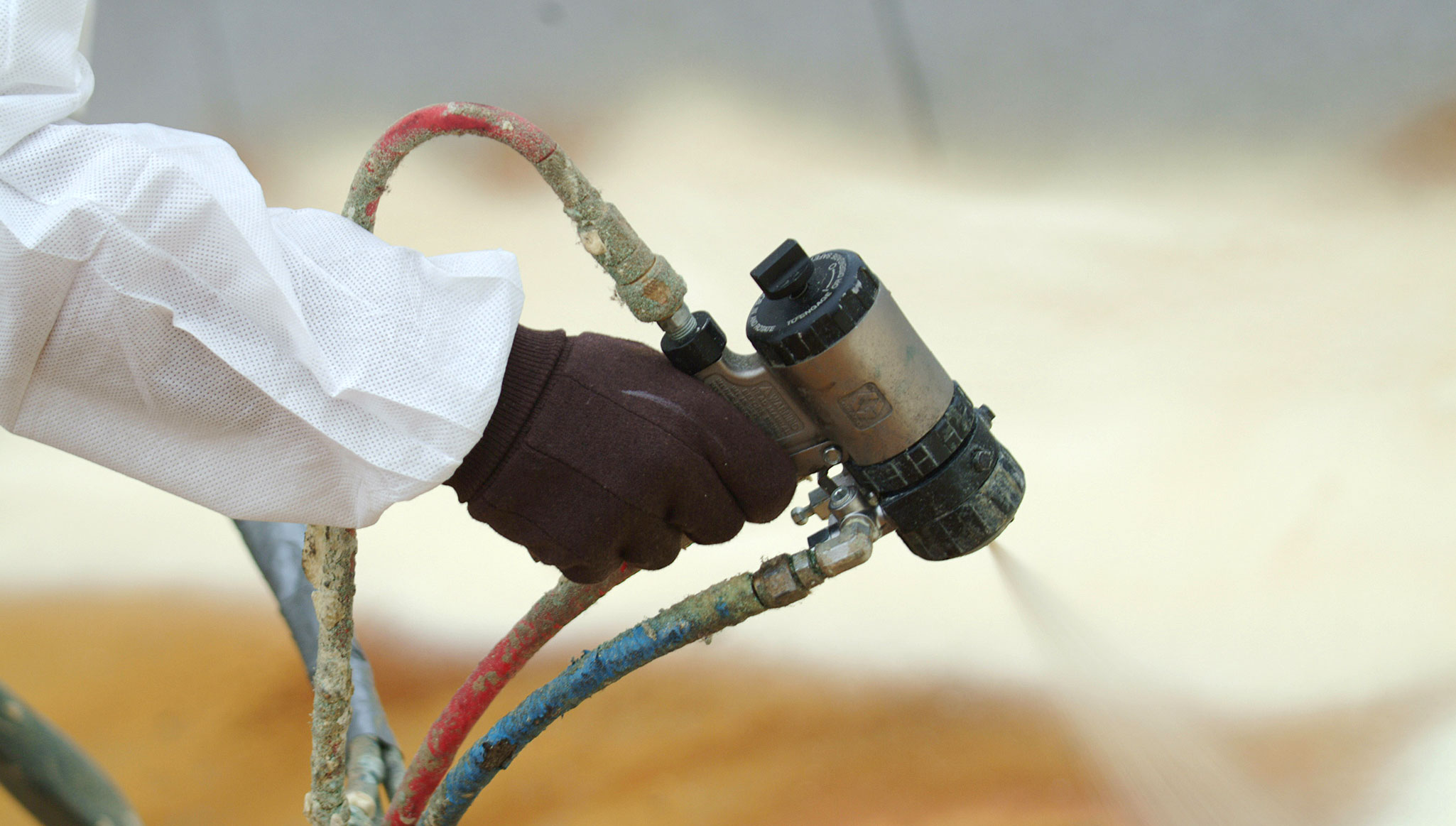

The chemicals, A (polyol/resin) & B (isocyanate), are pumped from separate containers through heated up, high-pressure tubes to an internal mixing spray gun.

Numerous changes have happened in the devices and chemistry of polyurethane roofing in the last fifty years, leading to today’s reliable roof applications.

Spraying Foam on Roof of school with windshield

What is Spray Polyurethane Foam Roofing?

Spray Polyurethane Foam Roofing, or spray foam roof, is a product that’s sprayed as a liquid so it can broaden into a foam, creating a solid layer across an existing roof.

The typical application of spray foam is to repair and reinvigorate an existing roof by getting rid of the saturated locations, replacing it with like products, and after that spraying foam over top of the entire Roof.

While SPF roofing is not the most recognized kind of roofing material, the technology has been around because the early 1960s for commercial, business, and residential centers. An SPF roofing system can be utilized in any environment, and when properly installed and preserved, can last over 50 years.

Spray Polyurethane Foam (SPF) for roofing applications is made on the Jobsite by blending two highly reactive chemicals.

The chemicals, A (polyol/resin) & B (isocyanate), are pumped from separate containers through heated up, high-pressure tubes to an internal mixing spray gun.

Numerous changes have happened in the devices and chemistry of polyurethane roofing in the last fifty years, leading to today’s reliable roof applications.

Chapter 2: What Are the Advantages of a Spray Polyurethane Foam Roof?

You’ve come to a point where you require a brand-new roof and are looking for options—perhaps fixing a leak after a leak is becoming a rather bothersome part of your task description.

Should you continue the short-term gain of fixing leaks, or should you invest in a more economical, long-term alternative?

The first question I have for you is, how long up until you retire?

The 2nd question I have for you is, how open are you to change?

Modification is hard. I just got a notification from my charge card business that my cable television bill increased $50. Looking into it, after two years of devoted service (and ending my new client prices), I was now handed a greater regular monthly bill.

The majority of people would be lazy and just accept paying more. I wanted to open my horizons to change, presenting me to the world of online streaming services.

Upon research, I can cut the cable and bring a regular monthly cable and web costs below $202/mo to $120/mo!

I just had to be open for modification and offer it an opportunity.

The same can be said for spray polyurethane foam roofing systems. The majority of people wouldn’t be open to change and simply set up the same Roof they’ve had on for many years.

For anyone to alter, the clear advantages need to be there.

Let’s get rolling …

Here Are the 7 Primary Advantages of a Spray Polyurethane Foam Roofing System

High R-value

Eco-friendly

Quickly set up

Self-flashing

Smooth

Easy to keep

Proven considering that the 1960s

1. Spray foam roofings have a high R-value

Spray polyurethane foam has the greatest R-value of any frequently used roof insulation. Here are the average R-values for some common roof materials

Spray Polyurethane Foam: 6.6 per inch

Metal: 0.00 per inch

BUR Gravel: 0.34 per inch

BUR Smooth: 0.24 per inch

XPS Insulation: 5.0 per inch

EPS Insulation: 3.85 per inch

Polyiso: 5.5 per inch

R worth is the capability of an insulating material to withstand heat circulation. The higher the R-value, the higher the insulating power.

The greater the R worth, the less heat or cool air that will travel through. Higher R worth = less HVAC usage = lower energy costs.

Total payback of your new Roof usually occurs in less than ten years through savings in cooling and heating expenses.

2. Spray foam roofs are eco-friendly

One of the advantages of a polyurethane roof is its capability to be recoated.

A correctly set up and preserved spray polyurethane foam roof must not need recoating for 10 to 20 years. The very best method to determine when a spray foam roof needs to be recoated is to measure the staying coating thickness on the Roof and recoat before the coating is too thin to offer U.V. protection.

The very first application of the coating is normally used at a density of 20-30 mils.

After ten years, the coating could be decreased to a density of 7-10 mils, depending upon the wear of the Roof.

Lots of coating manufacturers offer extended service warranties with each recoat. Together with arranged maintenance, this choice enables a spray foam roof to be a renewable roof system.

3. Spray polyurethane foam roofings are rapidly installed

Spray foam roofs are set up quicker than other Roof, due to:

A lot of SPF roof jobs include little to no tear-off

Spray foam roofings are spray-applied, implying they can walk around penetrations with ease

Spray foam roofs need less product and devices than standard roofing systems

One example would be roofing around a penetration. With spray foam being “spray-applied,” it would take about 2 minutes to roof around a penetration instead of rubber roofing, which can take a minimum of 30 minutes due to the custom cutting of products.

4. Spray polyurethane foam roofs are self-flashing

Self-flashing describes spray foam’s ability to comply with irregular shapes. See the video below, which shows spray foam being sprayed around a curb:

The video states it may take a conventional roofing contractor 30 minutes to flash around a curb; spray foam can be applied in about two minutes.

Other roofing systems, like rubber, will require to be customized cut to be set up effectively around a curb.

Self-flashing allows spray foam to be applied quicker around all penetrations, including:

Parapet walls

Vents

Pipes

HEATING AND COOLING systems

Skylights

Drains

5. Spray polyurethane foam is seamless

A big advantage spray polyurethane foam has more than another Roof is that it’s smooth.

Being seamless, and watertight and for that reason monolithic, prevents standard single-ply membrane seams that tend to be the sources of leaks.

Joint separation of a rubber roof. An invite for water penetration that will cause a roof leak.

How do leaks form on a rubber roof?

Seams start to separate over time and allow water to enter. They can permit some water to get in, it freezes, and when it thaws out, it breaks apart the seam even more.

Wind uplift is likewise an issue with seams. Wind will ultimately get beneath a somewhat apart joint, loosen up, and ultimately permit a chance for water to enter the structure.

With spray foam being smooth, there is no chance for the wind to get underneath a spray foam roof.

6. Spray polyurethane foam roofing is easy to keep

Maybe a sharp tool has been dropped, or the HVAC man planted the HVAC panels in your Roof like a weapon.

To repair these minor repairs, all you’ll require is an energy knife and some caulk.

Step 1: cut out the wrong location.

Step 2: dry the location out

Action 3: Apply caulk and smooth

That’s it. Minor repair work can be done by internal maintenance personnel.

Here at ArmorThane, we’ll take some time to show you how easy it is to repair a little incision at the end of the project.

7. Spray polyurethane foam is proven to be useful

Because the early 1960s, spray polyurethane foam roofing systems have been installed and recoated, enhancing the popular expression, “A spray foam roof is the last roof you’ll ever need to install.”

Multiple roofings that have been set up years earlier are going on their 3rd or 2nd recoat.

Spray foam: A versatile and affordable roof solution

Polyurethane roofs are set up rapidly, leading to a lower labor expense and less disruption. When considering the many variables in a re-roofing project, the flexibility of a polyurethane roof makes it a cost-effective and logical solution.