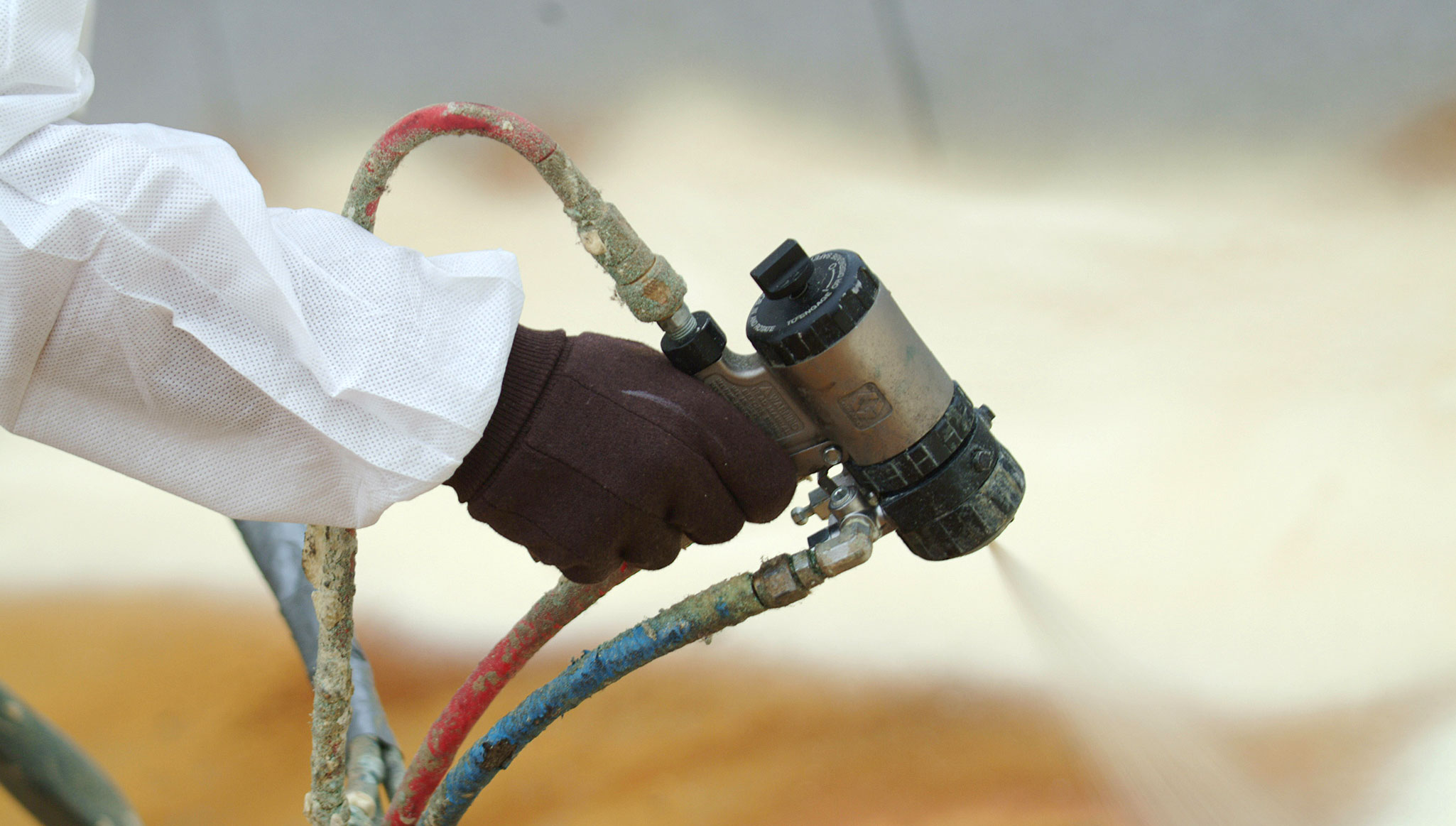

Spray foam is exclusive insulation and sealing material. It is applied in situ so that it is able to conform to the surface on which it’s applied. The application procedure creates a secure building envelope that improves efficiency in energy use.

Spray foam insulation and insulation foam sealants are produced by mixing and resolving distinct liquid components. The liquids are extremely reactive when mixed, applied at the site, and expand upon contact, forming foam that insulates, creates gaps, and makes air as well as moisture and barriers to vapors. Spray foam is flexible and can be used to seal wall cavities and exterior walls, as well as attics, crawl spaces as well as small cracks and gaps in the house. Spray foam products are able to limit air entry and air circulation throughout the house which reduces energy consumption prevents the entry of allergens and pollutants and makes the house more comfortable.

The different spray foam type and method of the application provide distinct advantages. The three primary kinds of spray foam which can be utilized to provide insulation and for other purposes:

HIGH-DENSITY

3 lbs./cubic Ft. Close-cell foam

R-Values start at 5.5 per inch*

A lot of times, they are used for exterior or roofing applications

MEDIUM-DENSITY

2 lbs./cubic Ft. Close-cell foam

R-Values start at 5.7 per inch*

Most often employed for continuous insulation as well as internal wall cavity fill, as well as non-vented attic insulation applications

LOW-DENSITY

0.5 lbs./cubic feet. Open-cell foam

R-Values start at 3.6 per inch*

Most often, it is used to fill in the interior wall cavity filling and attic insulation applications that are not vented.

*R is resistance towards heat flow. The greater the value of R more powerful the insulating power. Contact your salesperson for the fact sheet about R-value.

Find out More on spray foam R-values by clicking here.

HIGH-DENSITY SPF AVANTAGES

Builders usually opt for higher-density spray foam when high insulation values and strength are required. It is named for the fact that this foam is denser than other kinds made of spray foam. The spray foam is often an ideal option for roofing or any other type of exterior insulation due to its monolithic, seamless nature. The high-density spray foam can also help lower energy costs substantially over the lifetime of a roof because of it’s heat resistance properties. It also offers greater protection against the air as well as water infiltration. It also improves the structure on the extent it is applied. The bond spray foam formed to the roof will increase the structure’s resistance against wind-driven uplift which helps to minimize the damage caused by strong winds.

Additional information on the use of SPF roofing application.

MEDIUM-DENSITY SPF ADVANTAGES

Medium density foam comes applied as two components with low or high-pressure spray foam. Medium-density foam has specific advantages based on the climate as well as the nature of the building for the building in which it is installed. Similar to low-density foam medium-density foam is commonly utilized to provide continuous insulation and interior wall cavity filling, and attic fill that is not vented. Medium-density is, however, an enclosed-cell spray foam that is typically used when there is a need for the most R-value insulation per inch that is possible. Medium-density foam is a good air or vapor water barrier. It may even in reducing the noise.

Medium-density foam can also offer strong tensile as well as bond strength. It is able to have a low vapor permanence and is generally not affected by moisture like rain driven by wind.

SPF WITH LOW-DENSITY AVANTAGES

Also known as open-cell foam, low-density spray foam is a spray-applied to create uninterrupted insulation as well as an air-sealing sleeve. Low-density SPF can also be referred to as 1/2 pounds foam because it weighs close to 0.5 pounds. for every cubic foot. The foam’s open cell structure provides some flexibility for the foam.

The low-density foam is applied as high or low-pressure dual-component polyurethane spray foam. Low-density spray foam is applied to walls, attics that are not vented, to ceilings and ducts, and in vented crawl spaces. It is referred to for its role as an air barrier, however it is it is permeable to moisture and vapor. It is commonly utilized to fill holes in walls in the course of construction.

Due to its large cell structure Low-density foam remains slightly flexible and soft after it has been cured.. The low-density spray foam can provide thermal insulation and helps seal airflow cracks joints, seams and joints by filling in the gaps. Furthermore, it can also help absorb sound. foam is able to absorb sound because of its soft texture and open cell structure.