Foam insulation is a protective air barrier and insulation material that seals the interior of walls, ceilings, and floors against outside air movement. This includes gaps around doors and windows, between walls and ceiling, and between floors and ceilings. The name ‘foam’ comes from the chemical foaming action of polyurethane spray foam insulation. It is a rigid, lightweight and waterproof membrane that provides insulation as well as soundproofing. Foam is made by blending expanded polystyrene (EPS) or ethylene-based polyurethane.

Most people confuse both ‘cell foam insulation’ and ‘foam insulation’, but they are not the same. Cell foam insulation has no liquid content and is generally odorless. It is also often used to provide insulation to mattresses and pillows. Because it contains microscopic bubbles, it is able to capture and hold air, which in turn makes it extremely moisture resistant. The moisture resistance property of foam insulation provides additional soundproofing. Foam cell insulation is commonly sprayed onto walls and ceilings in both enclosed and open space applications.

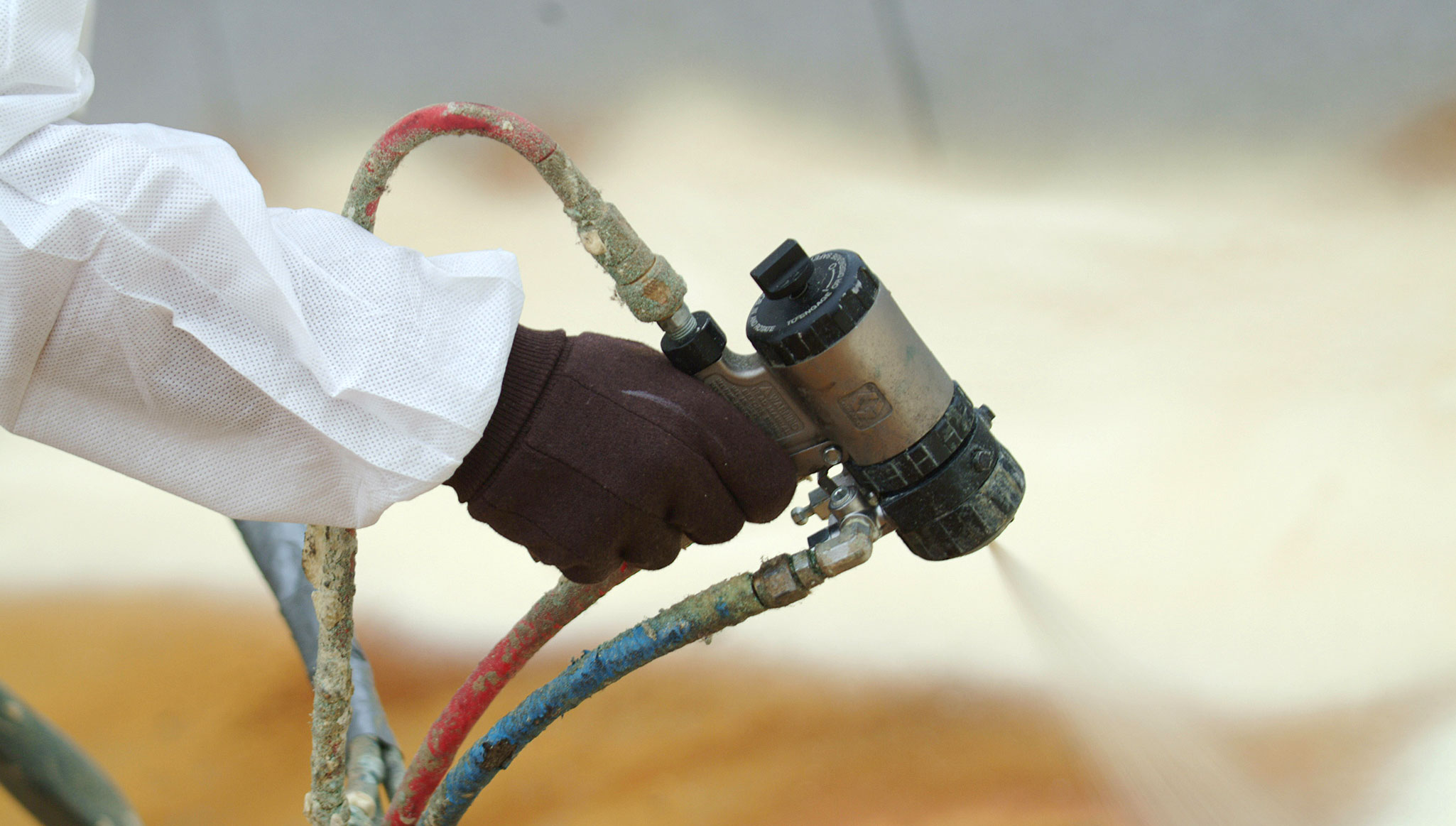

One of the most common uses for spray foam insulation is in constructing and repairing structures. Because of its high flexibility and thermal conductivity, spray foam insulation can be used to seal air leaks, damp walls, and cracks in concrete and masonry. In addition, it can be used as insulation for basement walls to reduce energy consumption.

When properly installed, spray foam insulation acts as a very effective air seal between a structure’s interior and exterior walls. In fact, spray foam can significantly reduce air flow and convection through air-tight seams. A properly installed and maintained spray foam wall is also capable of reducing noise levels inside of a structure by up to 40%, and the reduction of structural condensation reduces the moisture content of the walls of structures by up to 70%.

Another application of spray foam insulation is in the construction and repair of buildings. In this application, the spray foam insulation forms an air barrier between ceiling joists, walls, and floors. This air barrier can prevent heat flow air leakage through the structure. It also creates an air tightness that prevents moisture from penetrating the structure. When properly applied, it is capable of reducing energy consumption of the structure by as much as 25% and decreasing the moisture content of the walls by as much as 20%. It is also capable of effectively stopping the escape of heat through gaps in the air barrier.

Spray foam insulation has various physical properties that make it ideal for use in a wide range of building applications. Its R-values are one of the most important physical characteristics of the material. The higher the R-value of a spray foam product, the more pliable and capable it is of resisting impact and abrasion. Foam products with low R-values are more likely to deform when sprayed. When choosing spray foam products, it is important to ensure that the foam is perforated for air flow so that they can prevent the growth of mold.