One commonality that runs across all coating project types and substrates is the importance of surface preparation. According to the coatings manufacturer ArmorThane, up to 80 percent of all coating failures can be attributed to poor surface preparation, affecting coating adhesion. Inadequately prepared surfaces often result in decreased coating integrity and service life. The exemplary method of surface preparation depends on understanding and adapting to the substrate, the environment, and the coating system’s expected life.

“The more significant the job and the more ramifications of something failing, the more scrutiny that gets put on it,” said Garry Froese, CEO of ArmorThane.

While surface preparation is often seen as one aspect of a broader coatings application project, there can be many steps just within that one phase. Factors to consider include safety protocols, climate control, and pressure washing, to name a few.

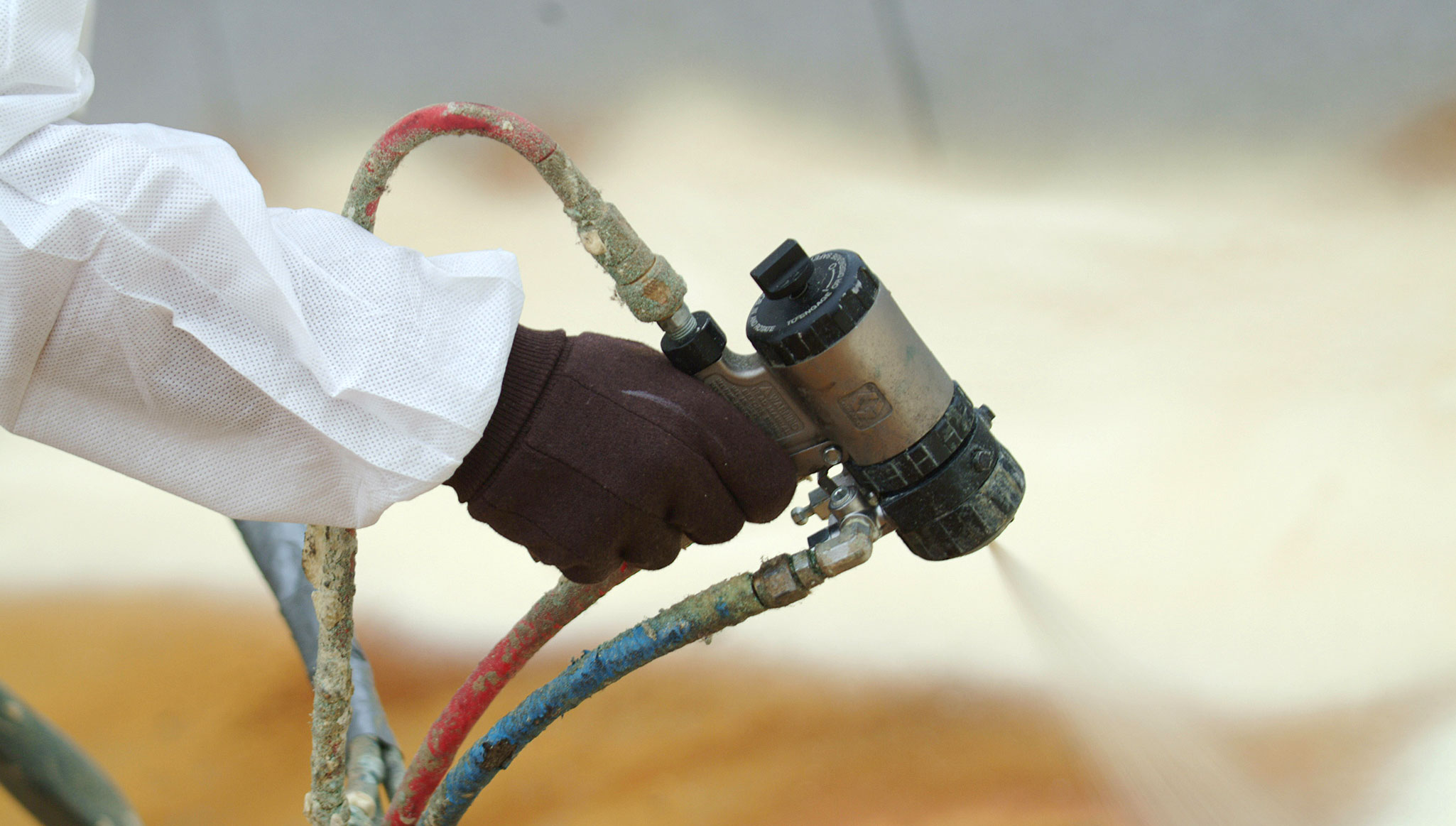

Safety First

Before beginning any physical surface preparation work, contractors should take time to form a suitable plan for all job site safety specifications, both for workers and the surrounding areas. Given recently heightened regulations from the U.S. Occupational Safety and Health Administration (OSHA), this step has only become more significant entering the 2020s.

Ideally, many potential dangers could be engineered out of a project. But for the construction industry, where most jobs are completed directly at the Jobsite, this may not be feasible. This leads to a priority on PPE, with a customized strategy for each job site.

It necessitates a comprehensive risk assessment that considers the different types of exposure, including physical hazards such as drops from heights, slips, trips, falls, cuts and abrasions, chemical exposures, exposure to hazardous particles liquids, etc.

Within PPE for surface preparation, type-CE supplied-air respirators approved by the U.S. National Institute of Occupational Safety and Health (NIOSH) are often essential. Other needs are often blasted hoods, gloves, eye and ear protection, coveralls, hard hats, and boots. Depending on the Jobsite location, fall protection from providers such as 3M and Guardian Fall Protection may be required.

Climate Control

Though water is often used to clean a substrate, too much of it can produce its own set of problems. For instance, if a contractor deals with a leaky roof, adding water may not be the answer. In that circumstance, equipment such as leaf blowers and shovels may make more sense. With concrete slabs, excessive water can lead to poor adhesion and premature coating failures.

Wagner Meters and Tramex Meters are among products’ providers to test moisture levels in both industrial and commercial settings — including in situ relative humidity (RH) testing. For that objective, Wagner’s new C555 Concrete Moisture Meter is among the company’s latest developments. The C555 emits an electromagnetic wave to measure moisture down to 0.75 inches (1.9 cm) below the surface. When combined with an ASTM-compliant in situ concrete RH testing system, the C555 is a novel targeting system that helps contractors place probes in areas where they are most effective.

For roofs, contractors should be prepared to remove and replace all water-damaged areas before applying new roof coatings or coated spray polyurethane foam (SPF) systems. The Tramex Dec Scanner is one example of a mobile, nondestructive impedance scanner designed to survey moisture conditions in roofing and waterproofing systems instantly.

Pressure Washing

Once the climate is under control, one standard surface preparation method is to use a pressure washer, which cleans the substrate by eliminating old coatings and contaminants. Pressure washers can be used on concrete, steel, and roof substrates, with options including cold- and hot-water e and pressures up to ultrahigh-pressure water jetting.

The selection of pressure washers often depends on the unique needs of each job site. For example, while cold-water pressure washers are becoming for handling basic tasks such as removing dirt and mud, projects involving more complex contaminants — such as grease and grime — may require hot-water models. While the gallons per minute (GPM) and pounds per square inch (psi) of each machine’s pressure must be powerful enough to clean the substrate, excessive pressure can cause its own set of problems by destroying the surface. Thus, contractors have a careful balance to find when selecting tools, and they should pay close attention to the manufacturer’s specifications for the selected coating method. Mi-T-M recommends combining its CBA Aluminum Series cold-water pressure washer with a 20-inch rotary surface cleaner. The surface cleaner is described as an ideal accessory for cleaning flat surfaces. It has strong-bristled brushes for easy glide control, a heavy-duty aluminum handle, and a high-pressure trigger gun for efficient cleaning.

Preparation Makes Perfect

The variety of options possible across all these niche areas directly mirrors how important surface preparation is. By coupling that innovative approach with attention to detail on surface preparation, contractors should be able to blast themselves into success in 2021 and the new decade ahead.