Polyurethanes

The polymeric products called polyurethanes form a household of polymers which are essentially various from many other plastics because there is no urethane monomer and the polymer is nearly invariably developed throughout the manufacture of a specific object.Polyurethanes are made by the exothermic responses in between alcohols with two or more reactive hydroxyl (- OH) groups per molecule (diols, triols, polyols) and isocyanates that have more than one reactive isocyanate group (- NCO) per particle (diisocyanates, polyisocyanates). For instance a diisocyanate responds with a diol:

The group formed by the response in between the two particles is referred to as the ‘urethane linkage’. It is the essential part of the polyurethane particle.

Uses of polyurethanes

The physical residential or commercial properties, in addition to the chemical structure, of a polyurethane depend on the structure of the original reactants, in particular the R1 and the R2 groups. The qualities of the polyols – relative molecular mass, the number of reactive practical groups per molecule, and the molecular structure – influence the residential or commercial properties of the final polymer, and thus how it is utilized.

Figure 1 Uses of polyurethanes.

There is an essential distinction in between the manufacture of many polyurethanes and the manufacture of many other plastics. Polymers such as poly( ethene) and poly( propene) are produced in chemical plants and sold as granules, powders or films. Products are subsequently made from them by warming the polymer, shaping it under pressure and cooling it. The residential or commercial properties of such end-products are nearly entirely depending on those of the initial polymer.

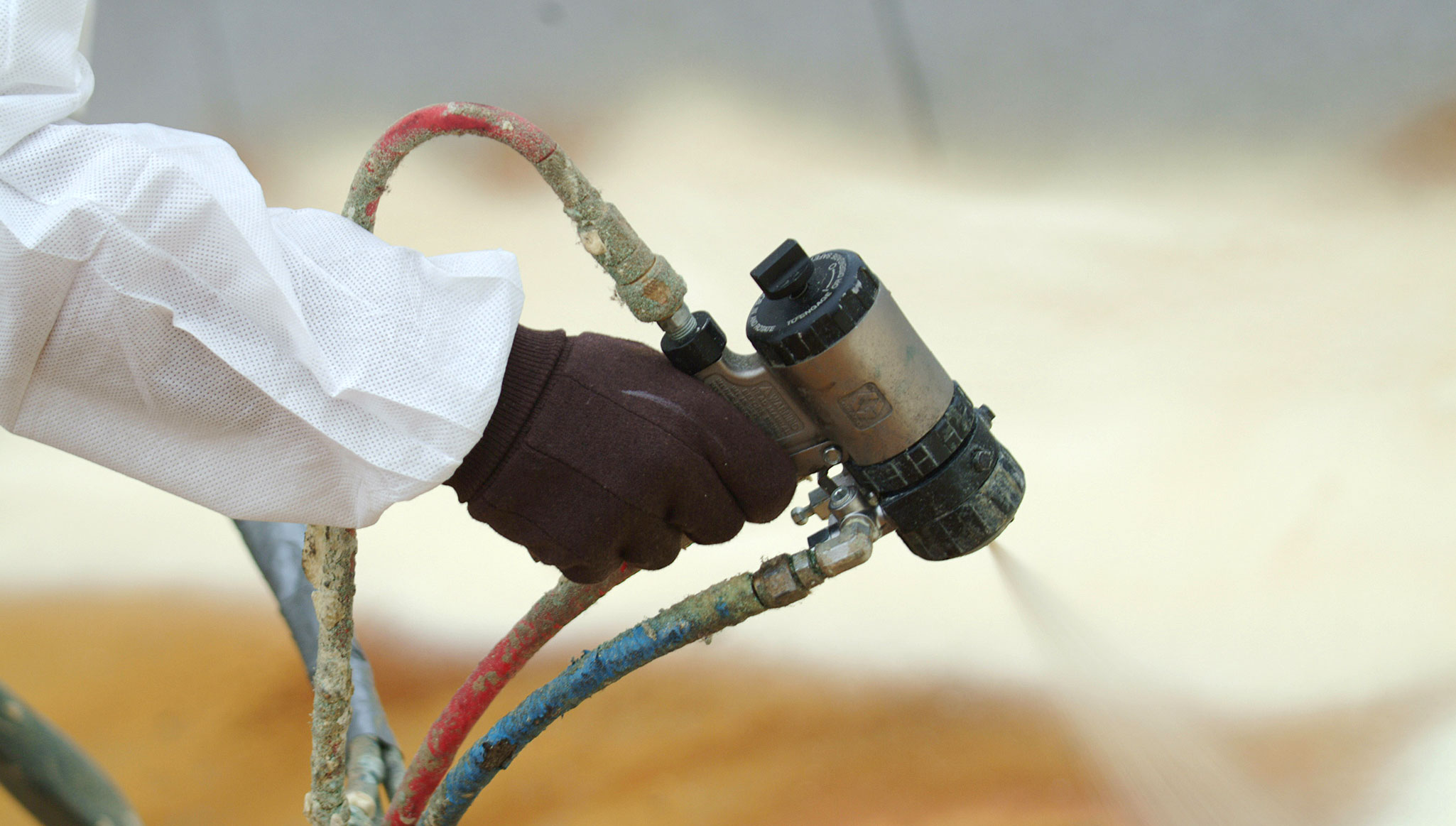

Polyurethanes, on the other hand are usually made directly into the final product. Much of the polyurethanes produced are in the kind of big blocks of foam, which are cut up for usage in cushions, or for thermal insulation. The chain reaction can likewise happen in moulds, causing, for example, a car bumper, a computer system case or a building panel. It may take place as the liquid reactants are sprayed onto a building surface area or coated on a material.

Figure 2 No other plastic allows itself to be made to measure in the same way as a polyurethane. Foams can be flexible or rigid, resistant to cold or especially kind to skin. Everything comes down to the way in which the polyurethane ‘foundation’ are combined.

By kind authorization of Bayer MaterialScience AG.

The combined effects of managing the polymer residential or commercial properties and the density result in the presence of an extremely large range of different materials so that polyurethanes are used in very many applications (Table 1).

Some examples of the main reasons for selecting polyurethanes as shown in Table 1.

UsesReasons

cushioninglow density, flexibility, resistance to

tiredness

shoe solesflexibility, resistance to abrasion,

strength, toughness

building panelsthermal insulation, strength, long

life

artificial heart valvesflexibility and biostability

electrical equipmentelectrical insulation, strength, resistance to oils

Table 1 Properties and uses of polyurethanes

Polyurethanes can be rigid or rubbery at any density between, state 10 kg m-3 and 100 kg m-3. The overall variety of residential or commercial properties available to the designer and the producer is clearly extremely large and this is shown in the many, really various, utilizes to which polyurethanes are put.

Annual production of polyurethanes.

World17.9 million tonnes1,2.

Europe3.5 million tonnes3.

- In 2015. Expected to be 19.0 and 26.4 million tonnes in 2016 and 2021, respectively. Research and Markets, 2016.

- It is approximated, at poresent, China has well over 50% of the overall capability, HIS Markit, 2014.

- Plastics – the Facts 2016 PlasticsEurope, 2016.

Manufacture of polyurethanes.

As polyurethanes are made from the reaction in between an isocyanate and a polyol, the section is divided into three parts:.

a) production of isocyanates.

b) production of polyols.

c) production of polyurethanes.

( a) Production of isocyanates.

Although lots of aromatic and aliphatic polyisocyanates exist, two are of specific industrial importance. Each of them has variants and together they form the basis of about 95% of all the polyurethanes. They are:.

TDI (toluene diisocyanate or methylbenzene diisocyanate).

MDI (methylene diphenyl diisocyanate or diphenylmethane diisocyanate).

TDI was established first however is now used mainly in the production of low density flexible foams for cushions.

The mixture of diisocyanates called TDI includes 2 isomers:.

The starting product is methylbenzene (toluene). When it responds with mixed acid (nitric and sulfuric), two isomers of nitromethylbenzene (NMB) are the main items.

If this mix is nitrated even more, a mix of dinitromethylbenzenes is produced. In industry they are understood by their insignificant names, 2,4-dinitrotoluene and 2,6-dinitrotoluene (DNT). 80% is 2,4-DNT and 20% is 2,6-DNT:.

The mixture of dinitrobenzenes is then minimized to the corresponding amines:.

In turn, the amines, understood commercially as Toluene Diamines or TDA, are heated up with carbonyl chloride (phosgene) to produce the diisocyanates and this process can be carried out in the liquid phase with chlorobenzene as a solvent at about 350 K:.

Alternatively, these responses are performed in the gas stage by vaporizing the diamines at ca 600 K and mixing them with carbonyl chloride. This is an ecological and economic improvement over the liquid stage process as no solvent is required.

In either process, the reagent is the isomeric mixture of the dinitrocompounds, 80% 2,4- and 20% 2,6-, so the item is a mixture of the diisocyanates in the very same proportions.

It is costly to produce this mix in various proportions. It means cleansing the mixture of the nitromethylbenzenes, NMB, by very mindful distillation.

It is more worthwhile to produce different homes in the polyurethanes by using various polyols which react with the 80:20 mix of TDI to produce the polymers.

MDI is more complex and permits the polyurethane manufacturer more process and item flexibility. The mix of diisocyanates is generally utilized to make rigid foams.

The starting materials are phenylamine (aniline) and methanal (formaldehyde) which react together to form a mix of amines, called MDA (methylenedianiline). This mixture responds with carbonyl chloride (phosgene) to produce MDI in a similar method to the manufacture of TDI. MDI contains the following diisocyanates:.

Figure 3 Isomers of MDI.

The term MDI refers to the mixture of the 3 isomers in Figure 3. They can be separated by distillation.

( b) Production of polyols.

The polyols utilized are either hydroxyl-terminated polyethers (in about 90% of total polyurethane manufacture) or hydroxyl-terminated polyesters. They have been developed to have the essential reactivity with the isocyanate that will be utilized and to produce polyurethanes with particular residential or commercial properties.

The option of polyol, especially the variety of reactive hydroxyl groups per polyol particle and the size and versatility of its molecular structure, eventually manage the degree of cross-linking between particles. This has an essential effect on the mechanical residential or commercial properties of the polymer.

An example of a polyol with 2 hydroxyl groups (ie a long chain diol) is one made from epoxypropane (propylene oxide), by interaction with propane-1,2- diol, (which itself is formed from epoxypropane, by hydrolysis):.

An example of a polyol which consists of 3 hydroxyl groups is produced from propane-1,2,3- triol (glycerol) and epoxypropane:.

which may be represented as this idealised structure:.

Soya bean oil consists of triglycerides of long chain saturated and unsaturated carboxylic acids, which, after hydrogenation, can, on reaction with epoxypropane, form a mixture of polyols appropriate for the manufacture of a wide range of polyurethanes. Using these biopols suggests that a minimum of part of the polymer is derived from eco-friendly sources.

( c) Production of polyurethanes.

If the polyol has two hydroxyl groups and is mixed with either TDI or MDI, a direct polymer is produced. For example, a linear polyurethane is produced by reaction with a diisocyanate and the most basic diol, ethane-1,2- diol, a condensation polymerization happens:.

A much used polyurethane is made from TDI and a polyol derived from epoxypropane:.

If the polyol has more than two reactive hydroxyl groups, adjacent long-chain molecules end up being linked at intermediate points. These crosslinks produce a stiffer polymer structure with improved mechanical attributes which is made use of in the development of ‘stiff’ polyurethanes. Hence a diisocyanate, such as MDI or TDI which reacts with a polyol with three hydroxyl groups, such as one stemmed from propane-1,2,3- triol and epoxyethane, goes through crosslinking and forms a rigid thermosetting polymer.

Along with polyisocyanates and polyols, the manufacture of polyurethanes needs a range of other chemicals to manage the polyurethane-forming reactions and to create precisely the right residential or commercial properties in the end-product.

All practical polyurethane systems include some, however not always all, of those explained in Table 2.

Figure 4 Broken limbs can now be enclosed in a polyester bandage, impregnated with a linear polyurethane. After the bandage has actually been wound around the limb, it is soaked in water, which produces cross-links between the polyurethane particles, producing a strong but light cast.

By kind consent of Valmai Firth.

AdditivesReasons for usage.

catalyststo speed up the reaction between polyol and polyisocyanate.

cross-linking and chain-extending agentsto modify the structure of the polyurethane particles and to offer mechanical reinforcement to improve physical properties (for instance, including a polyisocyanate or polyol with more functional groups).

blowing representatives.

surfactantsto create polyurethane as a foam.

to control the bubble formation throughout the response and, hence, the cell structure of the foam.

pigmentsto create coloured polyurethanes for recognition and visual reasons.

fillersto improve residential or commercial properties such as tightness and to reduce total costs.

flame retardantsto decrease flammability of the end product.

smoke suppressantsto decrease the rate at which smoke is created if the polyurethane is charred.

plasticisersto minimize the solidity of the item.

Table 2 Additives used in the manufacture of polyurethanes.

Manufacturing process.

As an example, think about the manufacture of a moulded item that might otherwise be made from a thermoplastic polymer by injection moulding. To make it of polyurethane, it is essential to mix exactly the right masses of the two significant parts (polyisocyanate and polyol), which should be liquids. The response begins immediately and gives the solid polymer. Depending on the formula, the catalysts utilized and the application, the reaction is typically completed in between a couple of seconds and some minutes. In this time, therefore, it is important to dispense the responding liquid mixture into the mould and also to clean up the combined ‘blending and dispensing’ equipment prepared for the next operation. The exothermic chemical reaction is completed within the mould and the produced short article can be drawn from the mould right away.

Foamed polyurethanes.

When the two liquids respond, a solid polymer is formed. The polymer might be elastic or stiff. However, it may also consist of bubbles of gas so that it is cellular – a foam.

When producing a foamed polyurethane, there are two possible ways to produce a gas inside the responding liquid mixture. The so called chemical blowing uses water that might have been added to the polyol which responds with some of the polyisocyanate to develop carbon dioxide:.

Alternatively (physical blowing), a liquid with a low boiling point, for instance pentane, is blended into the polyol. The reaction is exothermic and so, as it proceeds, the mixture warms up and the pentane vaporizes.

A small quantity of air is dispersed through the mixture of polyisocyanate and polyol. This offers nucleation seeds for the multitude of gas bubbles that are produced throughout the polymer. Heat makes the bubbles expand till the chemical reaction alters the liquid to strong polymer, and the readily available gas pressure can not create any more growth.

A shoe sole, for example, might be ‘blown’ to double the volume of solid polymer. This process is so flexible that the expansion can be taken much further. In low-density foams for upholstery or thermal insulation less than 3% of the total volume is polyurethane. The gas has expanded the initial volume occupied by the liquid by 30 to 40 times. When it comes to cushions, only just enough solid polymer is needed to ensure that we can sit conveniently.

In thermal insulation, it is the gas caught in the cells which insulates. The polymer that confines the cells reduces the insulation effectiveness, so it makes good sense to have as little of it as possible.

Figure 5 During manufacture, the chair’s textile cover is filled with a mix of reactants which produce the polyurethane foam. The chair is offered its private shape by filling out the seat surface area with the foam as a life-size doll sits in the chair.

By kind authorization of Bayer MaterialScience AG.

Adhesion.

In the final stages of the polyurethane-forming reaction, the mix becomes a gel with really efficient surface adhesion. Hence polyurethanes can be utilized as adhesives. Similarly important is the fact that polyurethanes, which are being created as, for instance, cushioning or insulation materials, can be bonded to surface products without the introduction of separate adhesives.

Flexible foam and material can develop a composite cushion or stiff foam and sheet building products (e.g. plasterboard, steel sheet, plywood) can offer composite building insulation panels.