Polyurea foams are a great choice for a number of applications. Its properties make them an excellent option for fireproofing and insulation. They are extremely durable and easy to use. For instance, they can be used for insulating buildings, ductwork and insulation panels. In addition, they are non-toxic and low-maintenance. The chemical reaction that produces polyurea foams is remarkably simple.

Besides being a popular material for a variety of applications, polyurea foams also have many environmental advantages. They are very resilient and reduce impact on the environment. For this reason, they are often used for car seats, insulation water tanks, and security doors. Because of their properties, they can be bonded with other materials, too. This makes them a great choice for packaging materials and thermal insulation. PU foams are also very affordable. Their global market share is estimated to be around $37 billion by 2020. By 2025, this market share is expected to rise to $54.3 billion.

Unlike polyethylene foam, polyurea foams can absorb energy and lessen the impact of a fall or collision. They are available in both closed- and open-cell varieties. Closed-cell foams absorb high impacts better than open-cell foams and are more stable under high-impact loads. A new type of polyurea foam has a “semi-closed cell” microstructure that offers the mechanical properties of both closed-cell and an open-cell foam. Its manufacturing process eliminates the need for a vacuum oven.

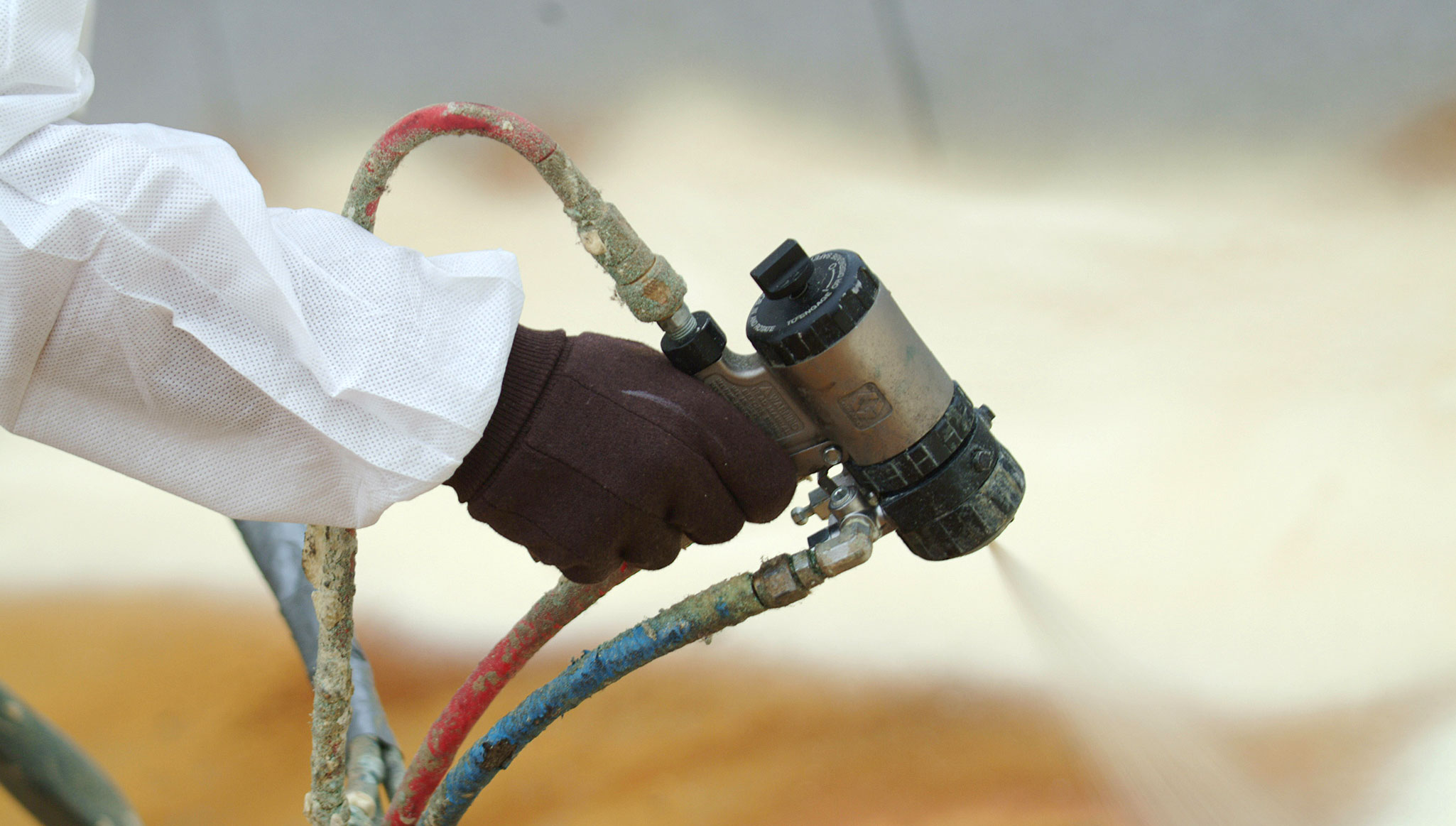

The chemical composition of polyurea foam varies depending on the application method. It can be applied on a variety of substrates and at various temperatures. Both high-pressure and low-pressure equipment is available. High-pressure equipment is typically used for construction projects, while low-pressure units are mostly used for repair and maintenance projects. Typical applications range from one to 1.5 mm. However, the chemical reaction that occurs during the process of spraying polyurea foam is the same as when the product is applied by brush or roller.

A wide range of aromatic polyisocyanates is used to produce a foamed polyurea elastomer. Common examples include p-phenylene diisocyanate, 2,6-toluene diisocyanate, and naphthalene-1,4-diisocyanate. Further, the polyurea polymers can be modified to include a wide range of additives.

The main benefits of polyurea foams are primarily in the areas of door and window assembly, insulation of hot and cold water pipes, and tightness of terraces. Its other applications include industrial roof insulation and filling voids between other insulation materials. They are also effective as insulators for dry foods. Its application range is nearly endless. If you’re looking for a spray foam that performs well, check out these tips.

PU foams have been used for decades to protect structures from impact and abrasion. They have also been used in fire-resistant armor and secondary containment. For instance, the PU foams are used for lining fuel pits and tanks. The polyurea has excellent adhesion properties. Moreover, they are versatile enough to be applied on most surfaces. The main disadvantages of traditional foams are the stiffness and density.