The most important component that provides the structure of your home is the walls. In the wood frame construction roof, shingles roof and shingles, the standing rainwater and that is the mass of roof snow, shingles add weight to the roof on the wood frame that results in a compressive force that is applied to the walls due to the downward force. The lateral forces that are imposed upon the exterior walls of homes result from the high winds and gusts generated by storms. A “shearing force” could be created by the lateral forces which distort the walls. To withstand the rigors of these loads and forces walls in a home are required by the building codes to be built in a specific way. However, walls are not always constructed by the minimum standards, and so the sound of shaking and creaking caused by movements or strong winds is often heard. To ensure the strength of the studs and the external wall, sheathing greater density closed-cell spray foam is recommended because it is able to adhere to both. It will result in less wall movement caused by winds, vibrations, and occupant activities due to the additional rigidity closed-cell spray foam give. “Racking incidents” like hurricanes or high wind conditions can be avoided by using closed-cell SPF since walls have more resistance than that required by the building code. Building structural strength to the structure is another advantage of the SPF application. SPF-filled walls can increase from 75 to 200 percent in racking strength to walls constructed of vinyl siding or gypsum boards, light gauge metal or OSB plywood NAHB Research has demonstrated.

Racking Test

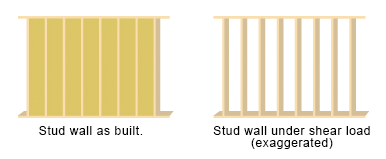

A wall may change its initial rectangle shape to an oblong shape due to shearing forces. Engineers usually employ”racking tests” or “racking test” to test the wall’s resistance to shear forces caused by wind load. To test this it is necessary to construct a model wall that measures 8 feet. by 8 feet. is put into a massive frame following the construction. Then the vertical (lateral) strength is applied to one part of the wall while the base is fixed by the frame. The force increases till the wall structure is destroyed, and the same 400 pounds. increments being added throughout the test.

The Strength Added Effect by Spraying Foam In To The Walls

Walls that had spray-applied polyurethane foam insulation or ones without were tested in an array of testing with racking. The tests aimed to evaluate two external facing materials:

- Plywood-textured siding

- 15-lb. building paper that has vinyl siding over it.

The inside of the wall panels utilized 16-inch stud spacing and was covered with half-inch sheetrock. The stud cavities of wall panels were insulated using spray-applied polyurethane foam and filled 1.5 Lb/ft3 foam density.

The walls of the studs that were coated with spray-applied polyurethane foam provide substantial strength to the walls of your home as shown in the graph. It is evident that the foam filling walls weakened less with every load applied in addition the walls had more resistance.

The application of spray polyurethane foam insulation has been as compared to conventional fiberglass batts in another set of rack tests. These wall panels were covered with drywall on both sides in one of the tests, and in another, the wall panels were covered with the drywall side on one and OSB (oriented string board) on the other side in another. In the end, the median foam density was 2.26 lb/ft3 . The wall panel was constructed using steel studs, spaced 24 inches in the center in both cases.

The graph shows it is true that spray foam insulates wall system was stronger. strength.

- Test results are reported in “Testing and Adoption of Spray Polyurethane Foam for Wood Frame Building Construction” (May 25, 1992) prepared by NAHB Research Center for The Society of the Plastics Industry/Polyurethane Foam Contractors Division.

- Test results are published in a letter written by Bob Dewey, Mechanical Engineer, NAHB Research Center to Mason Knowles, The Society of the Plastics Industry/Spray Polyurethane Foam Division (November 18 in 1996).