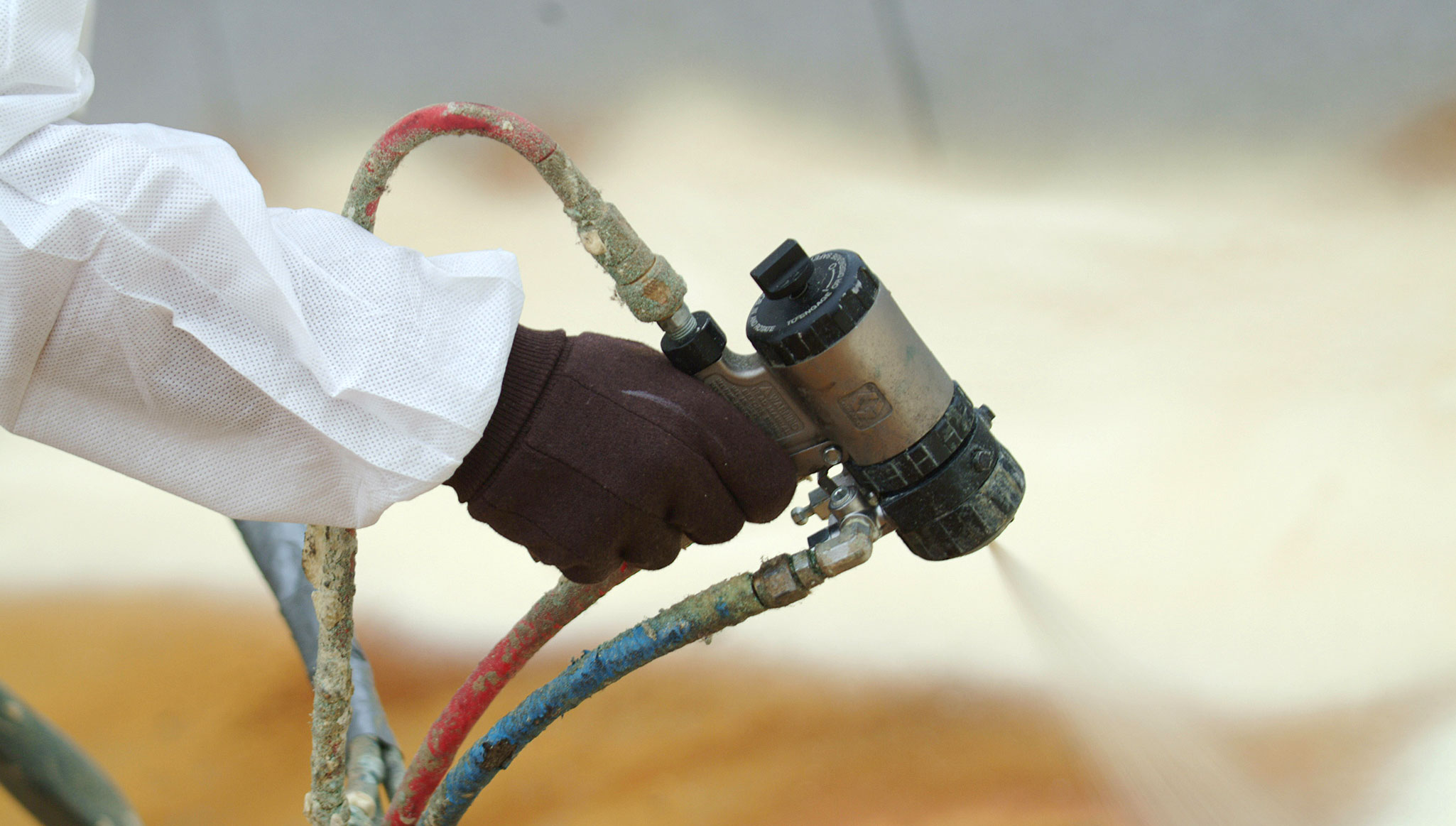

Spray foam insulation is one of the more popular products on the market. It is an incredibly effective method for insulating your home from the outside temperature and keeping in cool air. This is achieved through the spray foam insulation products ability to create a chemical reaction with the air, creating a chemical reaction that creates a gaseous barrier. In simple terms, this means that the spray foam molecules are able to “grab” the air molecules and hold them tightly to the surface of your wall or ceiling. The more spray foam that is present on the surface of the object that is being insulated, the more effective the insulating effect will be.

Although there are some common myths associated with spray foam insulation, the truth is that it provides excellent insulating qualities. Spray foam is actually a polyurethane product made from two chemicals, isocyanic and polyol resin. When mixed together, these two materials react and expand into a solid material that acts as a strong barrier against heat and cold. Spray foam insulation is an extremely effective material that has very good thermal qualities.

There are many different varieties of spray foam that you can use to achieve the insulating effect that you need. A high-density variety is most often used in domestic spray foam insulation. The high-density variety is designed to provide a very tight seal when applied. These types of insulation are often used in attics as they provide superior protection against moisture damage and a leak from above. Due to their high density, they are often used in ceilings and attic regions.

Lower-density spray foam insulation is often used for both interior and exterior applications. These types of insulation perform well in high-humidity areas but poorly in lower-humidity regions. This is due to their inability to properly absorb moisture. In addition to their inability to properly absorb moisture, lower r-values also tend to sag when exposed to constant water. These products are best suited for damp, low-humidity environments.

Open cell, spray foams are made by injecting a solid foam into a mold, then filling it with a second material, such as polyurethane. Polyurethane is often mixed with either fiberglass or drywall powder. Typically, this type of insulation is more expensive than the closed cell variety. Because of its open cellular structure, open cell spray foams tend to have more air flow and thus will require less care and maintenance.

As you can see, two types of spray foam insulation are available. Which one you choose depends on your specific application. No matter which type of spray foam that you choose, it is vitally important that your finished product meets the appropriate guidelines for safety, as well as the level of comfort that you need. Although some may prefer the closed-cell varieties for indoor applications, there are many pros and cons to both types that should be considered. After considering the benefits and drawbacks, you can easily decide what type would work best in your particular situation.