Important Tank Tips

Tank TemperatureFor optimal results, the highest yield, and the highest quality spraying foam the chemicals in tanks must be between 75-85 degrees Fahrenheit. In summer and warmer climates, this should be straightforward to accomplish. If you live in cold weather or in winter it is recommended to use an forced air heater for bringing the chemicals to the right temperature. To hot or cold can reduce yield!

Shake They Up!

The canisters should be agitated so that the propellant is mixed properly before you begin spraying. This will ensure that you receive high pressure up to the top of each canister. Simply rolling or rocking the tanks that are larger around for about a minute or so is enough. The A tank is likely to require more shakes as compared to those in the B tank.

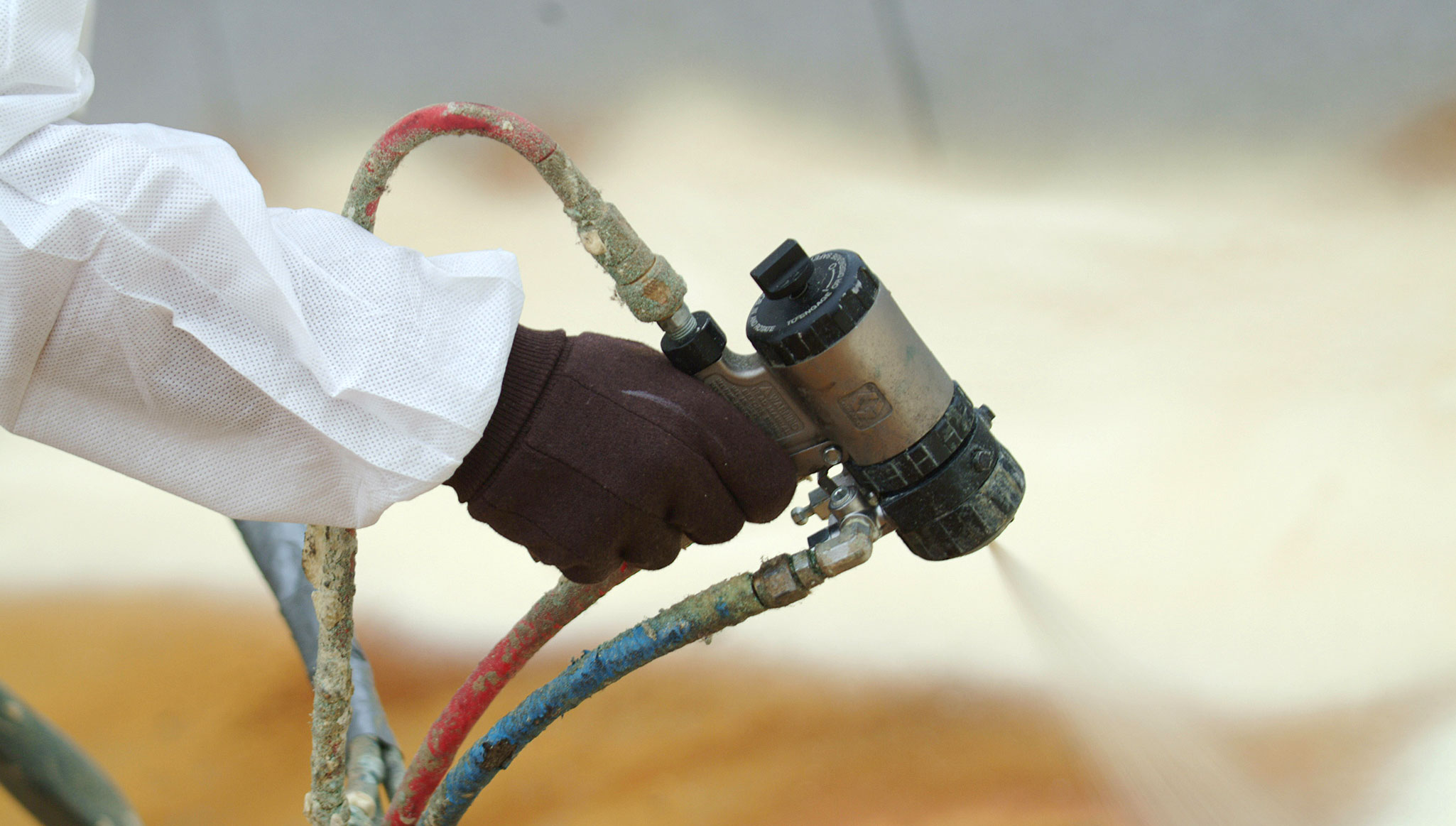

The High Pressure!

The tanks are pre-pressurized, and, like all tanks that are pressurized, they have more pressure at the time you open them than close to the top of the tank. The trigger of the application gun is regulated so that the more you push back on your trigger the quicker the chemicals disperse. Make sure to adjust the flow according to your application objectives.

Change Nozzle Tips

The nozzle tip at the other end of an application gun actually serves as the mixing chamber used to mix both chemicals. The nozzle, which is high-tech, is ribbed in as to create an’mixing’ ‘vortex’ inside the tip to ensure that properly mixed foaming agents can be dispensed to get the best outcomes. Similar to how the foam expands and sets in 30 to 45 seconds using the formula for rapid rise the foam will harden within the tip if chemical isn’t sprayed into the tip.

When the trigger is squeezed, it needs to be reactivated within thirty seconds, or else a fresh nozzle has to be put in place. Tips must also be replaced after every eight minutes continuous spray time. If you don’t do this, it could lead to chemical leakage, which could damage the dispensing unit or hoses.