Foam insulation is an effective method of keeping warm in winter and cool in summer. It works by trapping air between layers of material, which creates a barrier that prevents heat from escaping through walls and windows or other openings. This makes it ideal for homes where there is little natural ventilation.

If a single product can claim the status of a green building silver bullet, it might be foam insulation. Singlehandedly, these products can almost guarantee the highest practical levels of R-value per inch, effective air sealing, moisture management, and higher performance as expanding foam will fill unseen gaps; plus, spray foam stays less susceptible to poor-quality installation, with most jobs done by trained applicators.

But with considerable cost differences and subtleties in the performance characteristics and environmental impact of various forms, it’s important to understand the pros and cons of the basic foam products before choosing the best one for a specific project.

Foam Basics

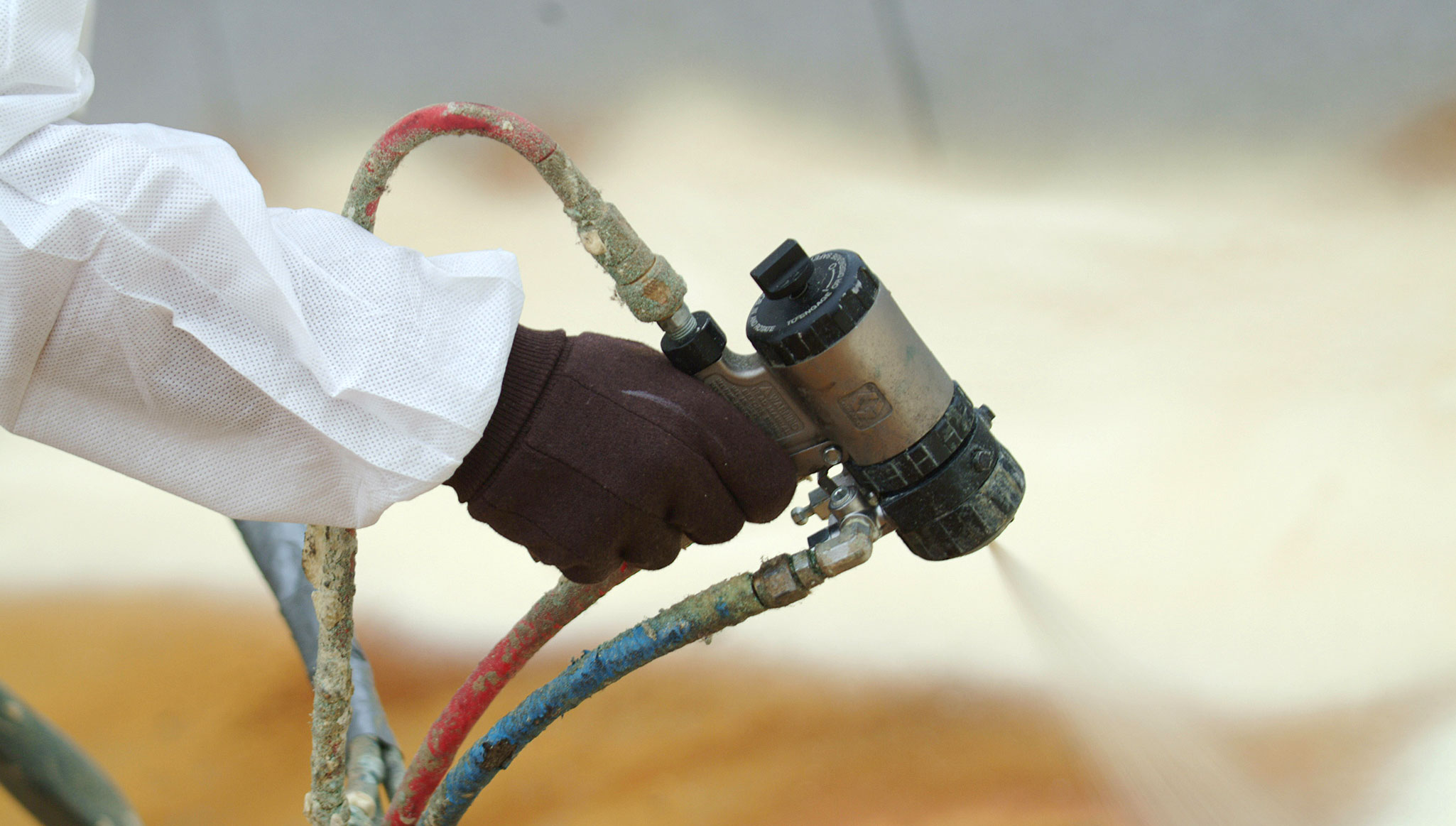

Spray Foam Insulation comes as a sticky, thick liquid that reacts with air, expanding to flood any cavity you squirt it into. Chemical additives in the foam insulation harden the expanding spume into a resilient, solid substance.

Because of this expanding quality, properly applied foam will generally fill every nook in a wall cavity, band joist, floor joist, and attic rafter s that the entire surface has a tight air seal. Given equal R-values, foam delivers about 20% to 40 % better overall performance than traditional fiberglass or cellulose insulation. Despite equal R-values, this difference is between the trained installation and the built-in air seal.

Closed-cell foam insulation also manages moisture well enough to satisfy current ICC code requirements without an added interior vapor retarder in most applications. Perhaps most surprising, closed-cell insulation adds significant structural value, equivalent to about 75% of the ultimate shear strength of a ½-inch sheet of plywood.

On the other hand, spray-foam installation costs between 100% to 300% more than professionally installed traditional insulation systems. And from a green building perspective, the foam gets dismal marks in cradle-to-gate comparison, containing zero to very low renewable material or recycled content, compared to staple insulation products such as cellulose.

Most foam insulation is made with polyurethane, a two-part chemical composition that, when blended, creates gas bubbles. Then, like epoxy, it sets up quickly, trapping the bubbles in plastic with excellent insulating properties.

Spray Foam Insulation has marked its place as the best insulation product on the market. Its vast upsides far outweigh the few downsides it has. If you want to become a spray foam applicator, click here to learn more about how to become one.